FastFRAME®

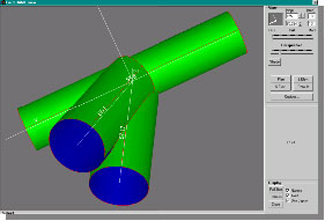

For use in large scale complex spaceframe construction to produce the data and layout, including the joint detail. A typical feature in the design of steel pipe frames is multiple pipes joining at one node point and intersecting each other.

COMPLEX TUBE & PIPE DEVELOPMENTS

FastFRAME® is a powerful production tool that can save hundreds of hours in the design stage of complex space frame developments. Complete structural frames can be completed in days! Of equal value, the extraction of fabrication data needed for processing is simple so you can validate the structure before processing begins.

FastFRAME® imports DXF/DWG drawings from steel detailing programs and provides all of the intersection details for single and multi-pipe intersections, including sequencing for construction. FastFRAME® can model individual nodes which you can view from any angle in wireframe or 3D. Even very complex detail can be viewed and checked. Details include full weld preparation information to International Standards, ensuring that the cut is accurate, even allowing for a continuously varying bevel.

FastFRAME® is suitable for the production of flat patterns for rolling, 'Wrap Patterns' or CNC controlled machinery. Developments can be used for NC controlled machinery or cut by hand. Output data is generally as patterns via conventional printer or plotter. Manual Wrap-around templates can also be created for users without specialist equipment. DXF output allows you to process the ends on your cutting equipment. Each element can be processed via Analogue or CNC controlled pipe cutting machines.

FastFRAME® highlights :

- Saves hundreds of hours in design, costing and 'right first time' fabrication.

- Input the member node co-ordinates and the steel pipe size or cut and paste from Excel or CSV. All data can be edited inside the system.

- The extraction of shop floor data is easy, detailed and relevant.

- The system automatically gives warnings to guarantee that the structure is correct.

- Provides the member node diagram, including the steel pipe cutting chart, cutting procedure, welding and assembly.

- Bevel support: Provides 3-6 axis numerical control bevel and transversal cuts. This means you don't have to do any manual weld preparation (no more sitting there with an angle grinder to get 'bite'!)

FastFRAME® works as a standalone system however the program is complemented by FastPIPE. Contact us to obtain a price for these type of specialist projects.