FastCAM® MTO™

FastCAM® MTO™ is a spreadsheet program specific to steel takeoff that allows you to automate and digitally capture all of the pertinent detail of drawings. Provides the fastest method of entering materials into 'sortable' electronic lists for estimating and factory production. Do a take-off once and get it right first time. Create lists in seconds...sort on material, section, type.. export the data, create reports, BOMs, lists, production sheets etc. You'll never have to re-type material lists again!

Steel Estimating Software

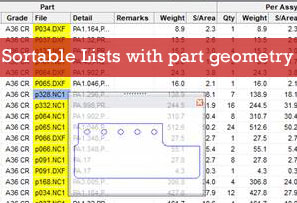

FastCAM® MTO™ is a steel estimating solution for steel service centers, detailers and fabricators. Plate and sections can be easily sorted and displayed with relevant detail such as mass, surface area, & quantities. It quickly creates sortable, organised lists that are very useful for estimators and others in the fabrication stream, including production. It contains full specifications for cut steel components in one digital exchange file.

Apart from the basic collating of entire lists of parts for steel fabrication, the program can also create a wide range of Reports or Lists useful for purchasing, estimating, and different stages of fabrication. These include scheduling and sorting components for sub-assemblies. Items can also be sorted by the following:

- Facility: IE Several building at the same location, e.g. sort all the data into Building A and Building B.

- Drawings: All items for a drawing or drawing set.

- Assemblies: Groups of parts to make up complete assemblies, e.g. a Portal Frame.

- Items: A complete list of all items sorted by the above criteria.

Universal exchange file for fabricated parts!

BOM's are often needed because a DXF file doesn't have an electronic property to convey material, thickness or quantity. FastCAM® MTO™ solves this problem by retaining the part geometry for plate and long product. For profiled items this includes complex geometry for outside and inside penetrations including drilled holes and marking. For long product this will include mitre, drilled holes and robotic copes.FastCAM® MTO™ provides the ideal solution for digital job file exchange along the supply chain. However, regardless of the ability and usefulness of sending the MTO data to a third party, MTO provides substantial benefits to anyone estimating, scheduling or fabricating steel structures or any substantial assembly in the metal industry.

The interface is designed around the user being quite familiar with steel fabrication, planning and processes. A user familiar with detail drafting would be best suited to using MTO as a natural extension to their work.

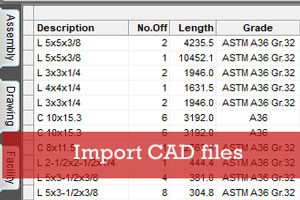

Import CAD files: FastCAM® MTO™ has various functions to automate and speed the importation of CAD files. You can even pre-set the Material and Thickness for all the files you select at the time of import and for precise data verification, the vertical scales are exaggerated to provide clarity and zoom facilities are provided.

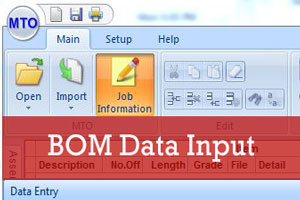

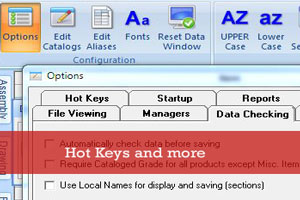

Enter data spreadsheet style: Command line data entry is made faster with predictive text and the program has drop down catalogue selection lists for sections. Color coded prompts guide you through the requirements and the Job Details sections, (Assembly, Drawing, Facility & Item) have mouse over tabbed flyouts to provide helpful function descriptions. A graphics screen is used for visual checking of the data as it is entered and a diagnostic feature flags data entry Errors & Warnings.

FastCAM® MTO™ highlights :

- FastCAM® MTO™ imports DSTV (NC1) and DXF/DWG (2D).

- Also imports FastCAM® .CAM (plate) files and FastBEAM™ .FBV (structural) files.

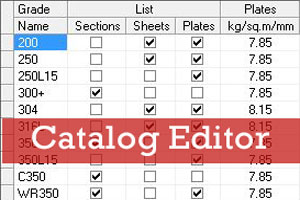

- Inbuilt catalogs for all Standard Sections.

- Catalog editor allows you to import, update and maintain your own list.

- Ability to setup alias names for non-standard sections or where names vary from supplier or manufacturer.

- Inch or Metric Data input/output.

- Cut or paste to & from Excel, Word and most Window Applications.

- Data includes mass and surface area of all items.

- The different reports display the data as editable or as a summary.

- Compatible with other FastCAM® products however no other software is required.

- The MTO file format can be exchanged with other MTO users and fed directly into the FastCAM® QE™ system for instant optimized quotes based on exact stock sizes.

RFQ Automation

Your fully specified job file can be emailed to Steel Service Centers for faster quotation.