FastBEAM™ NC

Program structural products for processing by Beam-lines, Angle-lines, and Flat Bar Processors. These machines are used for drilling, punching and cutting of rolled shapes such as Beams, Channels, Angles, and Flat Bars. More specifically standard H, C(U), L, plus rectangular hollow sections (RHS), Flat bars, and T sections in some machines.

STRUCTURAL CUT STEEL COMPONENTS

FastBEAM™ is a unique program that allows you to specify structural components from drawings or DSTV files. For detailing directly from shop drawings the program offers a spreadsheet type data entry system which eliminates 'drafting'. You simply enter in the co-ordinates taken from the drawing. or import CAD files including BoCAD, X Steel and DSTV formats. FastBEAM™ also supports the latest XML format for DSTV

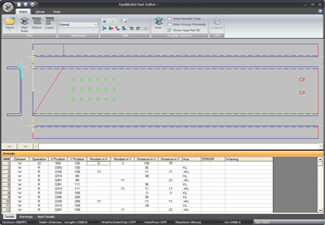

FastBEAM™ presents your programmed part in graphic form allowing for precise checking of dimensions. Designed around a third angle orthographic projection (as generally standard within the European Steel Fabrication Industry), the part image you see will match conventional workshop drawings so there is no need to interpret between a machine view and the shop drawing.

FastBEAM™ includes provision for mitre cuts and drill holes, and has checking facilities that ensures that holes are not drilled in incorrect locations such as too close to edges or web radius, or even other holes. FastBEAM™ also has the provision to easily program flange and web copes, including "manual" Copes where a coping function is not available on the machine. It does this by placing a drilled hole at the cope junction so it can be cut by hand without further laying out in the shop.

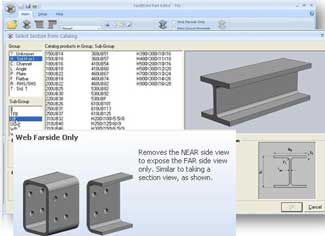

FastBEAM™ includes a comprehensive catalog of sections however the catalog can be modified at any time for Custom sections or to define aliases. Once an Alias is created it can be used for all future processing. This is especially useful for different manufacturers or imported sections. AISC standard connection drilling data for the ends of each section can be called up for a beam with just a few key-strokes. You can also prepare NC programs for different machines with the same procedures.

The person entering the data doesn't need to know anything about the actual operation of the Beam line. All the limits, restrictions and peculiarities of the particular machine are built into the programming software. Multiple machines with differing layouts and code requirements can be all driven with FastBEAM™. This approach allows for a single common interface between all machines regardless of output required.

FastBEAM™ highlights :

- Reads DSTV data from several structural detailing systems.

- Inch and Metric Data with both fractional and decimal notation.

- Fast drawing take-off: familiar Windows interface and spreadsheet-like data entry.

- Full graphic display for easy dimension checking to ensure accuracy.

- Provision for drilled holes, penetrations & slotted holes.

- Optimized drill sequencing minimizes machine travel.

- Concatenated functionality (puts similar items together in the one program).

- Automatic angle calculations (No more trig calculations).

- Easy to use Graphic Coping and Mitring makes programming a breeze.

- Optional DSTV output.

CAD INTERFACE As well as manual data input, FastBEAM™ supports CAD data from many sources including BoCAD, X Steel and DSTV formats. FastBEAM™ also supports the latest XML format for DSTV and is able to nest DSTV files and optimize stock via complimentary FastCAM® products MTO and FastCAM® QE™.

The output of FastBEAM™ can be customised to suit most machine brands such as: Peddinghaus, Ficep, Vernet, Kaltenbach, Wagner and most Saw/Drill/punch lines. It is also adaptable to older renovated machines with new retro-fitted CNCs. In addition, FastBEAM™ can now optionally output DSTV files so DSTV can be used as a Neutral file format for many new beamlines like the Python X.

NOTE: FastBEAM™ (with NC output) is quoted on a machine-by-machine basis, dependent on the make & model, functions fitted (drilling, sawing, coping, hard stamping etc). As Drill & Beamline equipment can vary significantly, we will require clear documentation of your equipment in order to ascertain suitability. A sketch of the machine is useful to us in preparing a quote.

Do you need to Optimize your stock?

Companion programs

You can nest DSTV files and optimize stock via complimentary quoting products FastCAM® MTO™ and FastCAM® QE™.